PRODUCTS

Home Freeze Drying Machine

Havion Home Freeze Dryer: Compact, quiet, ideal for families, homesteaders, and outdoor enthusiasts. Preserves fruits, eggs, and meals with durable, easy-clean stainless steel trays. Processes 4-25kg per batch, with remote control via Havion Home App (iOS/Android).

Commercial Freeze Dryer

Havion Commercial Freeze Dryer: trusted by food businesses for extended freshness. Durable stainless steel, ideal for cafes, farms, and mid-scale producers. 50-300kg batch capacity with integrated design for streamlined operation and efficiency.

Industrial Freeze Drying Systems

Havion Industrial Freeze Drying Systems: Designed for large-scale food processors, with 600-3,000 kg batch capacity. CE and ISO 9001 compliant, ensuring high-quality standards. Features advanced remote monitoring for 24/7 performance tracking and real-time operational efficiency.

Havion has redefined freeze drying technology with a complete range of home, commercial and industrial-grade systems. From preserving family meals to large-scale food production, Havion’s innovative technology ensures 99.9% nutrient preservation while significantly reducing drying time.

Advanced Drying Technology

Havion’s proprietary TriCore Freeze Drying Optimization Technology enhances moisture removal efficiency, outperforming traditional freeze-drying systems in both speed and energy efficiency.

Global Compliance

All Havion commercial freeze-drying systems meet CE, ISO 9001, and RoHS international standards.

Freeze drying — also known as lyophilization — is a modern dehydration technique that keeps products as close to fresh as possible. It’s changing the way industries preserve quality, nutrition, and shelf life. Here’s why:

Keeps Taste and Nutrition Intact

By removing moisture at low temperatures, freeze drying preserves flavor, color, and nutrients. Unlike heat-based food drying, which can destroy delicate vitamins and change textures, freeze drying maintains the product’s original qualities. The result is nearly identical to the fresh version—ideal for fruits, vegetables, and ready-made meals. This makes freeze drying superior to traditional food dehydrators, which can compromise taste and nutritional value due to the higher temperatures involved.

Shelf Life That Lasts Decades

With moisture reduced to less than 3%, freeze-dried products naturally resist spoilage and microbial growth. No preservatives or cold storage are needed—just store in a dry place and enjoy freshness for up to 25 years. This long shelf life is one of the major reasons many industries, from frozen food producers to pharmaceuticals, rely on freeze drying. Products like instant coffee and meat are preserved effectively, keeping their original texture and taste for years without refrigeration.

Works Across Many Industries

From food and beverages to pharmaceuticals and biotech, freeze drying adapts to powders, liquids, and solids. It’s widely used for creating nutritional supplements, instant coffee, and delicate biological products. The flexibility of the process makes it ideal for purchasing in bulk across various sectors, as it meets the demand for quality preservation without compromising product integrity.

Protects Structure and Texture

The sublimation process maintains your product’s shape and integrity. Whether it’s a fruit slice or a sensitive compound, the original form is preserved without shrinkage or damage. The use of trays in freeze drying ensures that the structure is retained during the process, making it ideal for delicate items like fruits,meat,candy or flowers.

Perfect for Long-Term Storage

Freeze drying offers lightweight, long shelf life, and stability—without the need for additives or refrigeration. It’s ideal for building products that travel far and last longer, such as military rations or emergency preparedness food kits. This makes it an excellent choice for consumers interested in purchasing freeze-dried products for long-term storage or for industries that need to produce large quantities of preserved goods with minimal space requirements.

Information and Community

As interest in freeze drying grows, so does the community around it. From online forums to YouTube videos, there’s a wealth of information available for anyone considering freeze dryers, whether for personal use or large-scale production. The community is a great resource for tips, troubleshooting, and understanding how to get the best results from your equipment.

Price and Size Considerations

The price of a freeze dryer can vary greatly based on its size and intended use. Home models are typically more affordable, while industrial-sized machines are more expensive. The size you choose will depend on how much you plan to process at once, making it crucial to consider both your purchasing needs and available space. Whether for home use or commercial production, the right size ensures efficient operation and scalability.

Because Quality Shouldn’t Compromise

In a market that demands freshness, consistency, and convenience, freeze drying offers a reliable solution. It’s not just a process—it’s a commitment to preserving what matters most, whether that’s a fresh slice of fruit, a meat product, or a pharmaceutical compound.

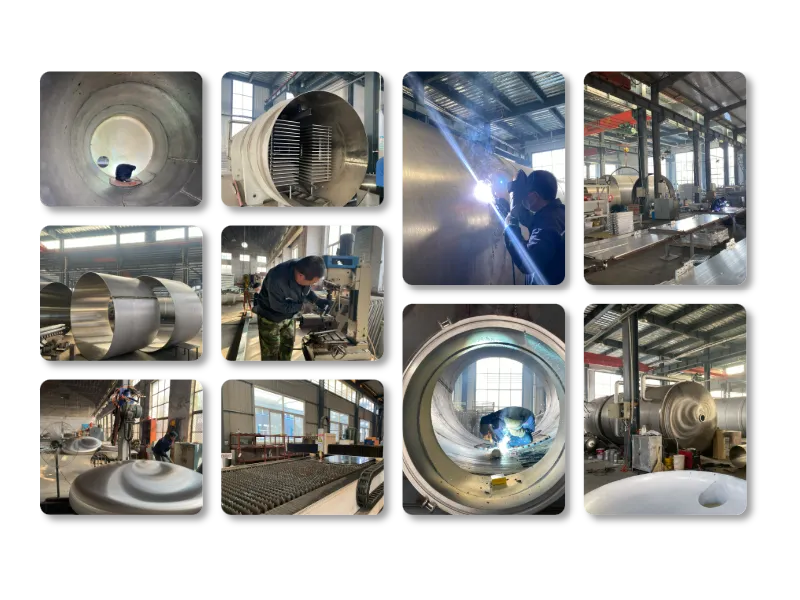

Havion TriCore Freeze Drying Technology

Proprietary Nano-Black Coating Technology

Utilizing our self-developed high-emissivity black surface treatment process, magnetron sputtering enhances heat absorption on heating plates, improving heat exchange efficiency by 18%-22% compared to conventional models. This innovation reduces energy consumption while accelerating drying speed.

Energy-Efficient System Architecture

Leveraging an extensive freeze-drying experimental database, our senior engineering team conducts dynamic modeling of key components, including refrigeration units, vacuum pumps, and ice condensers. This optimization reduces overall energy consumption by 8%-11% compared to traditional freeze dryers.

Enhanced Water Vapor Capture System

In collaboration with the Shanghai University of Science and Technology Freeze-Drying Laboratory, we pioneered the gradient water capture area distribution algorithm. By dynamically adjusting the condenser’s active surface in response to material sublimation rates, this technology improves water vapor capture efficiency by 9%, leading to shorter drying cycles and lower energy consumption.

COLLABORATIONS

GreenValley Foods Achieved 60% Output Growth with Havion Industrial Freeze Drying Systems.

“By upgrading to Havion’s industrial freeze dryers, we increased production capacity by 60% while reducing energy consumption by 30% – transforming our operational efficiency.”

“Evergreen Catering relies on Havion’s freeze dryer for improved efficiency and energy savings. Their excellent service and tailored solutions have greatly enhanced our operations. Highly recommend their quality equipment and support.”

Ready to see what freeze drying can do for your business? Let’s talk.