You can contact us for all your questions, opinions and suggestions.

Industrial Freeze Dryer

Havion specializes in high-efficiency, reliable, and energy-saving industrial freeze-drying equipment designed for large-scale production. Its self-developed TriCore Freeze Drying Technology offers the following advantages:

High Batch Yield: Optimized design to enhance production efficiency

Short Drying Cycle: Advanced sublimation technology to reduce drying time

Low Operating Cost: Energy-efficient system to minimize power consumption and maintenance costs

Our Comprehensive Services:

Equipment Design & Manufacturing: Customized solutions from our expert team

Installation & Commissioning: Ensuring fast and efficient system startup

Training & After-Sales Support: Technical assistance for long-term stable operation

Freeze Drying Process R&D: Helping optimize production workflows

Turnkey Project Services: One-stop solutions for all your freeze-drying needs

The Havion universal series includes six mainstream models, catering to various production scales to help you achieve optimal freeze-drying results.

Specification

| Model | FD600 | FD900 | FD1200 | FD1800 | FD2100 | FD2400 |

|---|---|---|---|---|---|---|

| Ice condenser temperature | -45°C | -45°C | -45°C | -45°C | -45°C | -45°C |

| Ice condenser capacity | >600L | >900L | >1200L | >1800L | >2100L | >2400L |

| Tray loading volume | 2.1m³ | 3.2m³ | 4.3m³ | 6.4m³ | 7.5m³ | 8.5m³ |

| Number of tray transport carts | 4units | 6units | 8units | 12units | 14units | 16units |

| Chamber footprint | 9.5m(L)*2.9m(W)*3.4m(H) | 10.8m(L)+3.1m(W)*4m(H) | 12m(L)*2.9m(W)*3.8m(H) | 18.5m(L)+3.1m(W)*4.4m(H) | 21m(L)+3.1m(W)*4.4m(H) | 23m(L)*3.1m(W)*4.4m(H) |

| Operating vacuum range | 30Pa-133Pa | 30Pa-133Pa | 30Pa-133Pa | 30Pa-133Pa | 30Pa-133Pa | 30Pa-133Pa |

| Weight | 11T | 15T | 18T | 25T | 28T | 30T |

| Usable tray area | 60.8m² | 91.5m² | 121.7m² | 182.5m² | 212.9m² | 243.3m² |

| Peak power requirement | 80.4KW | 120KW | 191.8KW | 286KW | 340KW | 372.7KW |

| Number of product trays | 136per cycle (2 sets supplied,total 272) | 204per cycle (2 sets supplied,total 408) | 272per cycle (2 sets supplied,total 544) | 408per cycle (2 sets supplied,total 916) | 476per cycle (2 sets supplied,total 952) | 544per cycle (2 sets supplied,total 1088) |

| Tray dimensions | 710*630*35mm | 710*630*35mm | 710*630*35mm | 710*630*35mm | 710*630*35mm | 710*630*35mm |

| Typical eatch load of product | 600kg | 900kg | 1200kg | 1800kg | 2100kg | 2400kg |

| Drying chamber shape | Cylindrical, Single door | Cylindrical, Single door | Cylindrical, Single door | Cylindrical, Single door | Cylindrical, Single door | Cylindrical, Single door |

| Heating method | Electric heating or Steam heating | Electric heating or Steam heating | Electric heating or Steam heating | Electric heating or Steam heating | Electric heating or Steam heating | Electric heating or Steam heating |

| Freezer storage | Included | Included | Included | Included | Included | Included |

| Condenser type | Internal, Rear-mounted | Internal, Rear-mounted | Internal, Rear-mounted | Internal, Rear-mounted | Internal, Rear-mounted | Internal, Rear-mounted |

| Installation type | Modular design | Modular design | Modular design | Modular design | Modular design | Modular design |

| Shelf temperature range | Normal temperature to 100°C | Normal temperature to 100°C | Normal temperature to 100°C | Normal temperature to 100°C | Normal temperature to 100°C | Normal temperature to 100°C |

| Drying chamber material | SUS304 Stainless steel | SUS304 Stainless steel | SUS304 Stainless steel | SUS304 Stainless steel | SUS304 Stainless steel | SUS304 Stainless steel |

Disclaimer: While every effort is made to provide accurate information, it is subject to change at any time. Performance figures are calculated and may vary in use due to different products and formulations.

Features

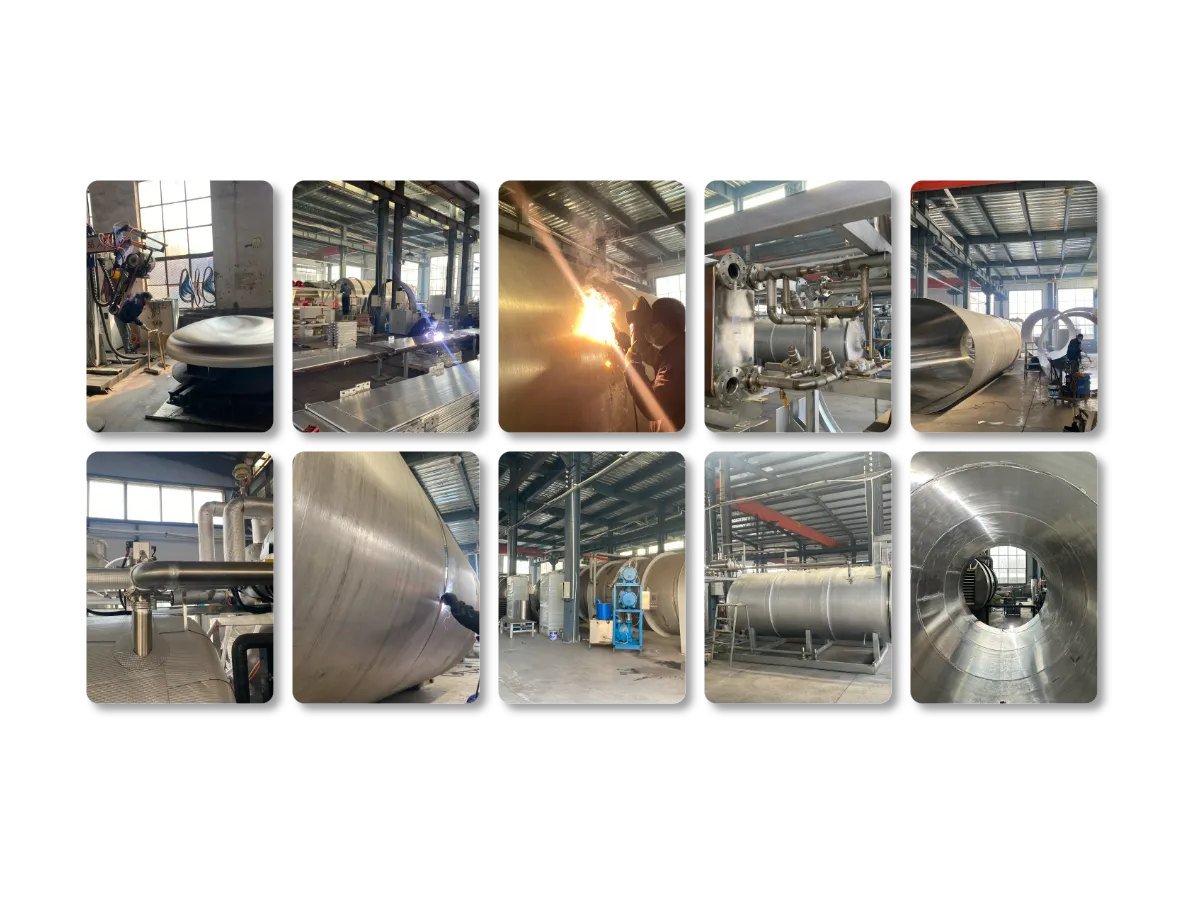

Structure & Design

Havion Industrial freeze dryers with independent subsystem design for quick on-site installation

Heavy-duty H-beam frame for stability and durability

Drying chamber made of 304 stainless steel, ensuring hygiene and safety for industrial food freeze dryer applications

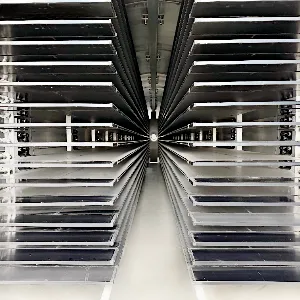

Shelves and trays made of anodized aluminum alloy for enhanced thermal conductivity

Dual-sided radiant heating with distilled water as the heating medium to prevent contamination

Separation of wet and dry areas to reduce cross-contamination during production

Low-temperature condenser can be integrated or installed separately to meet different industrial scale freeze dryer requirements

PLC touchscreen control system for efficient monitoring and operation

Technology & Efficiency

TriCore Freeze Drying Technology optimizes time, temperature, pressure, and production flow

Reduces energy consumption and labor costs while improving production efficiency and equipment reliability

Ensures uniform drying, high sublimation capacity, precise temperature, and vacuum control

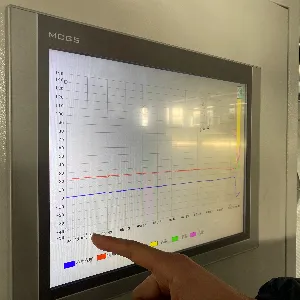

PLC system enables remote monitoring, recipe management, and user-friendly operation

Customization & Cost

Havion, a leading industrial freeze dryer manufacturer, offers both standard models and customized solutions.

Adjustable drying chamber size, shelf spacing, condenser capacity, and installation methods

Tailored freeze-drying solutions to help businesses enhance competitiveness

Industrial freeze dryer price varies depending on capacity, design, and additional features

Looking for an industrial freeze dryer for sale? Contact us for detailed specifications and pricing

Whether you need a large industrial size freeze dryer or a compact unit, we provide cost-effective options to fit your budget

For more information on industrial freeze dryer cost and custom solutions, get in touch with our team today!

Industrial Freeze Dryer System Overview

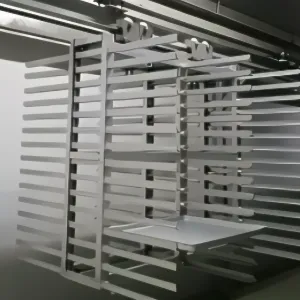

Overhead Rail Transport System

The product is quickly transported using a sliding trolley on the overhead rail. The freezing room, drying chamber, and pallet loading/unloading areas are connected, streamlining the production process and saving time and labor.

Product Freezing System

Products are quickly frozen in the freezing room.A 6-8 hour preparation shift can provide enough freeze-dried products for 24 hours.Follows the "first in, first out" principle.

Drying Sublimation System

Automatic control of the drying cycle.Simply close the drying chamber door, set the parameters, and press start, minimizing manual intervention.

Heat Supply System

Precise temperature control from room temperature to 90°C to optimize drying.

Vacuum System

High-efficiency vacuum pumps reach the required vacuum in under 15 minutes.Offers precise control for products with low freezing points.

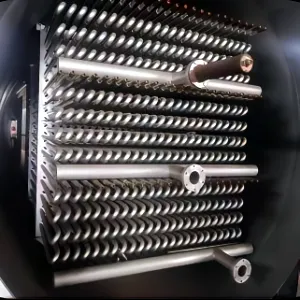

Refrigeration System

High-efficiency industrial compressors.Multiple units can share a common system, reducing energy consumption.

De-icing System

Water flushing ice melting system operates during batch intervals.Ice melting completes in about 40 minutes without affecting drying time.Simple, low-cost operation.

Control System

PLC industrial control system supports manual/automatic switching.Real-time control, process curve printing, and data storage.Ensures efficient and harmonious operation of freezing, drying, heating, vacuum, and cooling systems.

Video

What is the typical return on investment (ROI) for an industrial freeze dryer?

The ROI for an industrial freeze dryer depends on production scale, market demand, and product pricing. Generally, a well-operated freeze-dried food, pharmaceutical, or biotech facility can recover its investment within 1-3 years. The high added value and growing market demand for freeze-dried products make it a stable long-term investment.

How does freeze-drying technology provide a competitive market advantage?

Freeze-dried products offer superior quality, extended shelf life, and no need for preservatives, making them highly competitive in the food, pharmaceutical, and cosmetics industries. Compared to conventional drying methods, freeze-drying preserves the product’s nutrients and original structure, enhancing market acceptance and premium pricing.

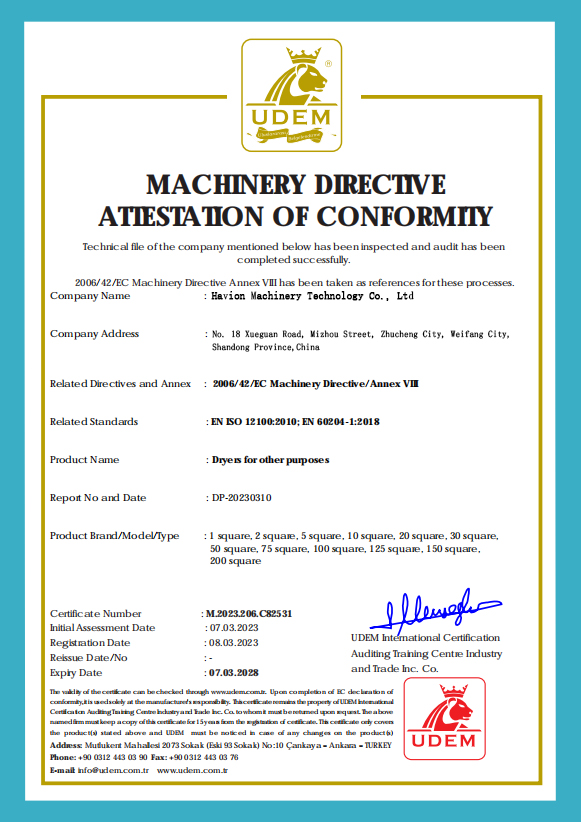

How do you ensure the quality of industrial freeze dryers meets international standards?

Our freeze dryers comply with ISO and GMP standards and are certified by international organizations such as CE and FDA. Additionally, our manufacturing processes undergo strict quality control to ensure equipment stability, durability, and high performance.

How can an industrial freeze dryer optimize energy consumption?

Modern freeze dryers use high-efficiency industrial compressors, intelligent temperature control systems, and energy recovery technologies to reduce power consumption significantly. Our systems support multi-stage condensation and vacuum control, improving energy efficiency by more than 30%.

What is the core working principle of a freeze dryer?

Freeze drying involves three main steps:

Freezing – The product is rapidly frozen to ultra-low temperatures (-40°C or lower).

Primary Drying (Sublimation) – Under vacuum, ice crystals in the product directly convert into vapor without passing through the liquid phase.

Secondary Drying (Desorption) – Any remaining bound moisture is removed to achieve the desired dryness level.

This process preserves the product’s nutrients, flavor, and structure.

How does the freeze dryer achieve intelligent operation?

Our freeze dryers are equipped with advanced PLC (Programmable Logic Controller) systems that enable real-time monitoring and precise control of temperature, vacuum pressure, and heating rates. Users can remotely monitor and adjust parameters to optimize production efficiency and product quality.

What materials are used in manufacturing freeze dryers to ensure durability and safety?

Our freeze dryers are primarily made of food-grade stainless steel (304 or 316L), ensuring corrosion resistance, easy cleaning, and compliance with food and pharmaceutical hygiene standards. Additionally, the vacuum system is built with high-strength alloy materials to ensure long-term stable operation.

What are the raw material requirements for freeze drying?

Raw materials suitable for freeze drying typically have high water content, such as fruits, vegetables, meats, dairy products, coffee, herbal medicines, and biotech products. Proper pre-processing (such as slicing and pre-freezing) can enhance the final freeze-drying quality.

What are the latest innovations in freeze-drying technology?

Recent advancements in freeze-drying technology include:

Intelligent Control – AI algorithms optimize drying curves for higher efficiency.

Energy-Saving Technologies – Multi-stage condensation and vacuum recycling reduce power consumption.

Continuous Freeze-Drying – Enables higher production capacity with automated loading/unloading systems.

Nano Freeze-Drying – Improves product texture, solubility, and rehydration performance.

How can product quality be ensured during the freeze-drying process?

Quality is ensured through intelligent control systems that precisely regulate temperature, pressure, and drying time to prevent collapse or oxidation. Additionally, optimized pre-treatment processes (such as flash freezing and uniform cutting) help maintain the best product appearance and rehydration capability.

How can production efficiency be improved when using an industrial freeze dryer?

Key methods to enhance efficiency include:

Optimizing freeze-drying curves to reduce unnecessary drying time.

Using pre-freezing systems to shorten batch processing time.

Implementing high-efficiency vacuum pumps and refrigeration systems to speed up cooling and vacuum extraction.

Automating loading and unloading systems to minimize manual labor.

Are maintenance costs for freeze dryers high?

Modern freeze dryers are designed with modular components, making maintenance relatively simple. Routine maintenance mainly involves:

Replacing vacuum pump oil periodically.

Cleaning condensers and heat exchangers to maintain efficiency.

Inspecting gaskets and seals for air leaks.

Proactive service strategies can reduce long-term operating costs, improve uptime, and enhance return on investment (ROI).

Why is the vacuum system critical to freeze drying?

The vacuum system allows moisture to sublimate at low temperatures, improving drying efficiency and preventing oxidation, which can degrade product quality. A high-performance vacuum pump can reach the required vacuum level within 15 minutes, ensuring continuous production.

Why are protection mechanisms essential in freeze dryers?

Our equipment includes multiple safety features such as over-temperature alarms, low-pressure protection, and automatic defrosting to ensure safe operation and prevent equipment damage.

What is the demand for freeze-dried products in the U.S. market?

The U.S. market has a growing demand for healthy, natural foods. Freeze-dried products, due to their additive-free nature and extended shelf life, are increasingly popular among consumers. Additionally, freeze-drying technology is widely used in the pet food, pharmaceutical, and biotechnology industries, making it a promising market for investment.

Industrial Freeze Dryer Applications

Industrial freeze dryers offer advanced solutions for preserving and processing a wide range of products while maintaining their original taste, nutrients, and structure. This technology is widely used across various industries, ensuring extended shelf life and premium quality.

Key Applications:

Food Preservation & Processing: Extends shelf life while retaining natural flavors and nutrients.

Fruits & Vegetables: Maintains color, texture, and taste for premium dried snacks.

Meat & Seafood: Ensures long-term storage without compromising protein integrity.

Candy & Confectionery: Creates unique textures and enhances product stability.

Pet Food: Provides highly nutritious, lightweight, and easily rehydrated options.

Nutritional Supplements: Preserves vitamins and bioactive compounds effectively.

Harvest Management: Reduces waste and ensures seasonal produce availability year-round.

Taste & Aroma Retention: Prevents oxidation, keeping products fresh and flavorful.

Innovative Packaging Solutions: Lightweight, moisture-proof packaging for global distribution.

Medication & Pharmaceuticals: Preserves active ingredients in vaccines and biotech products.

Therapeutic Applications: Used in biotechnology and regenerative medicine for cell preservation.

Industrial freeze drying is the key to high-quality, long-lasting products across multiple industries.

what food preservation

What Food Preservation Really Means: Strategies, Technologies, and Outcomes Food preservation refers to the set of techniques and processes used to slow down or halt the spoilage of food. At its core, it’s about extending the shelf life of food products and maintaining their nutritional value, flavor, and texture. Whether

Freeze Drying Process Steps Explained: From Ice to Shelf-Ready

Freeze-drying isn’t just a method—it’s a transformation. From juicy strawberries to injectable pharmaceuticals, the ability to preserve texture, structure, and biological activity rests on one thing: precision. But what exactly happens between raw material and final powder? Let’s walk through each step of the freeze-drying process and break it down

Behind the Cold: Unpacking the Freeze Drying Process Steps

Freeze drying, also known as lyophilization, preserves perishable materials by removing water through sublimation—transitioning from a solid directly into vapor without passing through the liquid phase. It’s not just a modern innovation; ancient civilizations, particularly the Incas, laid its foundation by storing food at high altitudes where cold nights and