You can contact us for all your questions, opinions and suggestions.

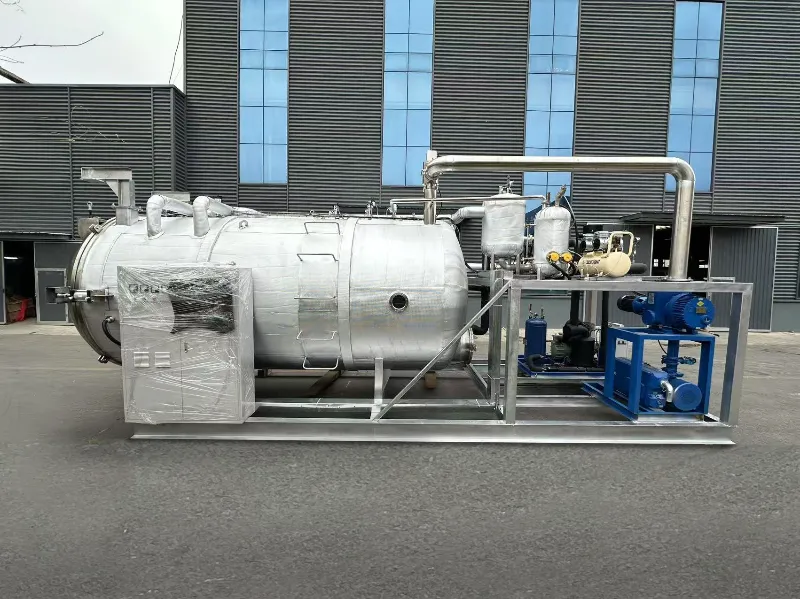

Commercial Freeze Dryer

Havion’s commercial freeze drying systems empower food processors, and agricultural producers with:

- TriCore Freeze-Dry Technology: Boost output by reducing cycle times by up to 40%. Our TriCore freeze drying technology improves heat transfer, vapor capture, and vacuum control in one system, increasing throughput without compromising product quality.

- Compact, Plug-and-Play Design: Space-saving and easy to integrate. The compact design fits into existing setups and installs quickly, making it ready for immediate use.

- Advanced Smart Control System: Precision and automation. The intelligent system monitors and adjusts key freeze-drying factors, ensuring consistent results and reducing manual work for better efficiency.

Specification

| Model | FD50 | FD100 | FD200 | FD300 |

|---|---|---|---|---|

| Ice condenser capacity | >50L | >100L | >200L | >300L |

| Usable tray area | 5.4m² | 10m² | 22m² | 30.4m² |

| Tray loading volume | 0.19m³ | 0.3m³ | 0.7m³ | 1.1m³ |

| Typical eatch load of product | 50kg | 100kg | 200kg | 300kg |

| Tray dimensions | 710*630*30mm | 790*630*30mm | 690*570*30mm | 710*630*35mm |

| Number of product trays | 12per cycle (2 sets supplied,total 24) | 20per cycle (2 sets supplied,total 40) | 56per cycle (2 sets supplied,total 112) | 68per cycle (2 sets supplied,total 136) |

| Number of tray transport carts | / | / | 2units | 2units |

| Ice condenser temperature | -45°C | -45°C | -45°C | -45°C |

| Operating vacuum range | 30Pa-133Pa | 30Pa-133Pa | 30Pa-133Pa | 30Pa-133Pa |

| Shelf temperature range | Normal temperature to 100°C | Normal temperature to 100°C | Normal temperature to 100°C | Normal temperature to 100°C |

| Heating method | Electric heating | Electric heating | Electric heating | Electric heating or Steam heating |

| Condenser type | Internal, Rear-mounted | Internal, Rear-mounted | Internal, Rear-mounted | Internal, Rear-mounted |

| Drying chamber material | SUS304 Stainless steel | SUS304 Stainless steel | SUS304 Stainless steel | SUS304 Stainless steel |

| Drying chamber shape | Cylindrical, Single door | Cylindrical, Single door | Cylindrical, Single door | Cylindrical, Single door |

| Installation type | Compact integrated design | Compact integrated design | Compact integrated design | Compact integrated design or Modular design |

| Freezer storage | Not Included | Not Included | Not Included | Not Included |

| Peak power requirement | 35KW | 79.45KW | 136KW | 67.4KW |

| Chamber footprint | 5m(L)*1.7m(W)*2.2(H) | 5.63m(L)1.8m(W)2.6m(H) | 8m(L)*2.7m(W)*3.5m(H) | 8.5m(L)*3.1m(W)*3.4(H) |

| Weight | 5T | 6.2T | 7.5T | 9T |

Disclaimer: While every effort is made to provide accurate information, it is subject to change at any time. Performance figures are calculated and may vary in use due to different products and formulations.

Features

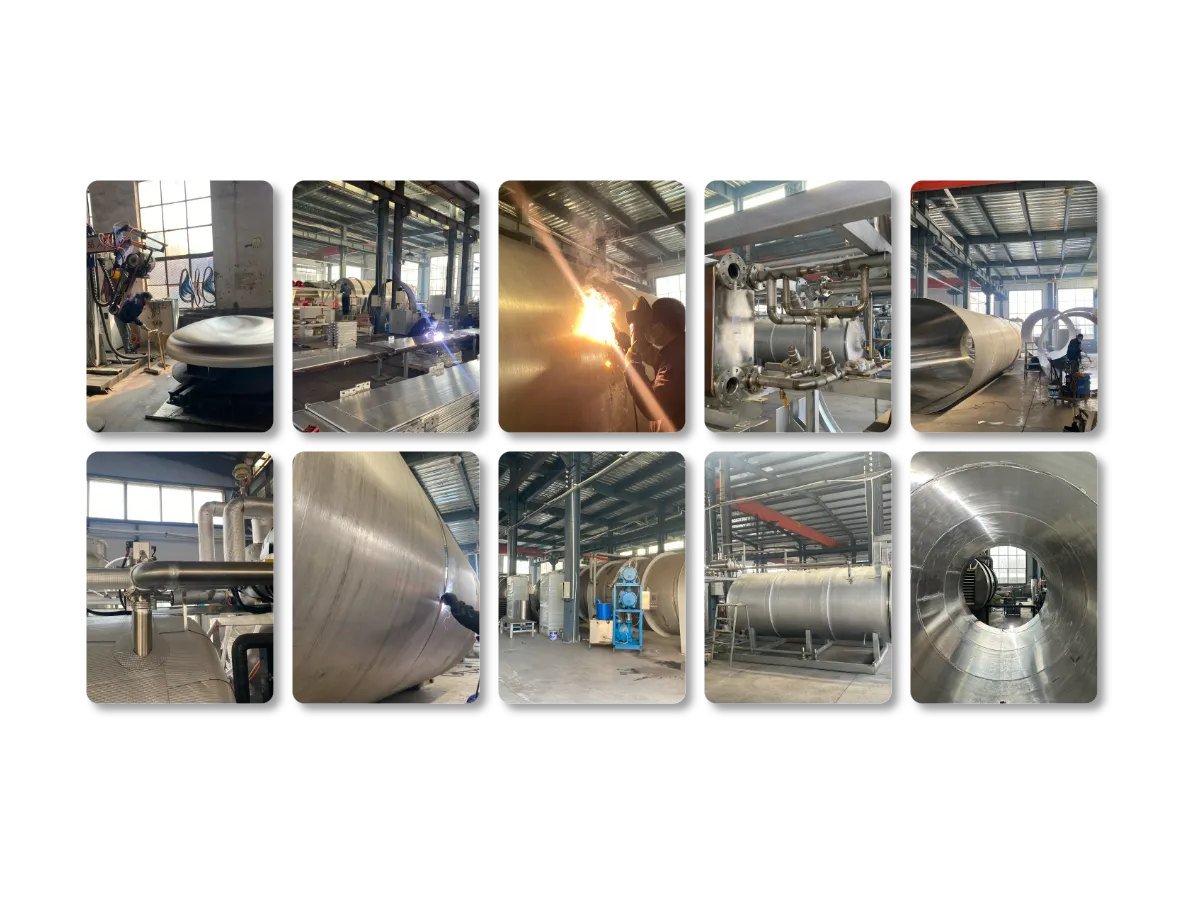

Havion Commercial Freeze Dryer System Overview

The Havion Commercial Freeze Dryer series is designed for high efficiency, low energy consumption, and strict compliance with hygiene standards. It is widely used in industries such as food processing, pet food, CBD extraction, cosmetics, and dietary supplements. Whether you’re scaling up from laboratory-sized equipment or seeking high-capacity solutions, Havion provides customizable configurations. Our equipment offers batch production capacities ranging from 50kg to 300kg, meeting diverse production needs.

Technical Advantages

Proprietary TriCore Freeze Drying Optimization Technology

Havion’s unique TriCore system integrates three core technologies to enhance drying efficiency and reduce operational costs:

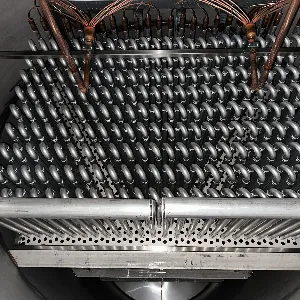

Nano Black Coating Technology

A nano black coating developed through magnetron sputtering significantly enhances the heat absorption capacity of the heating plates. Tests show that the heat exchange efficiency improves by 18-22% compared to traditional aluminum surfaces, effectively shortening drying cycles and improving energy efficiency.Energy-Saving System Architecture

Based on extensive experimental data and real-time on-site monitoring, dynamic thermal models for the condenser, vacuum pump, and compressor have been developed. These models optimize system performance, helping reduce energy consumption by 8-11%.Enhanced Vapor Capture Algorithm

In collaboration with Shanghai University of Science and Technology, Havion has introduced a gradient distribution algorithm that dynamically adjusts the active surface area of the condenser based on real-time sublimation rates, improving vapor capture efficiency by 9% and further shortening total drying time.

Design Highlights

Compact Plug-and-Play Design

All subsystems are pre-installed and factory-tested for quick deployment, with no additional calibration required. The compact design is ideal for various factory layouts, maximizing space utilization.Integrated Layout Architecture

All system components (including shelves, trays, condenser, and control system) are integrated into a compact, unified structure, eliminating unnecessary connections and saving space. This design simplifies transportation and installation, reduces maintenance complexity, and ensures efficient collaboration between system modules. The integrated design maintains high reliability and stability while reducing space and labor requirements.Safe Heating Medium

High-purity distilled water is used as the internal heat transfer medium in the shelves. In the event of a leak, it will not contaminate the product, ensuring the safety of both the system and the product.

Economic and Operational Advantages

No Cold Chain Logistics Required

Freeze-dried products can be stored at room temperature, eliminating the reliance on cold chain logistics and reducing storage and transportation costs.Improved Transport Efficiency

Freeze-dried products are lightweight and compact, making them easy to distribute and reducing transportation costs.Lower Operating Costs

Through optimized design and intelligent automation, the Havion system significantly reduces energy and labor costs.Convenient Maintenance

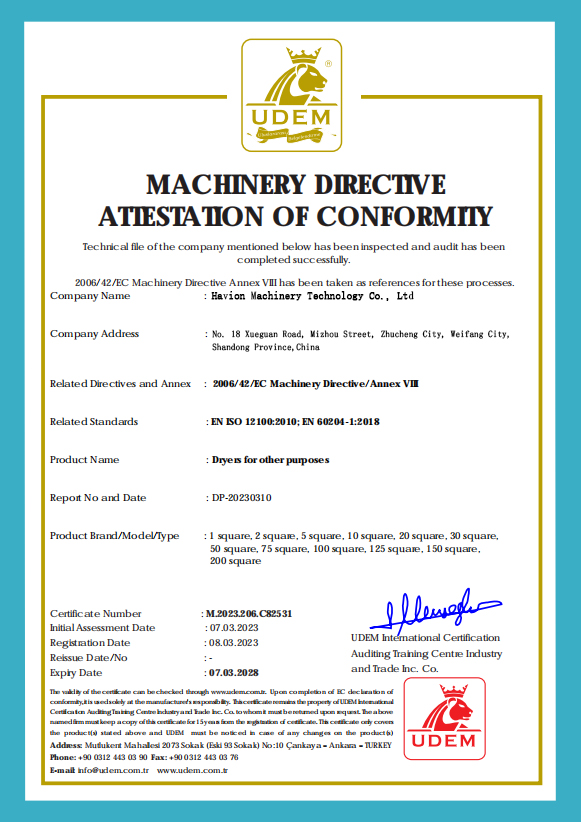

All product-contacting parts are made of food-grade materials and high-grade stainless steel, designed for easy cleaning and maintenance. This ensures compliance with CE and ISO9001 standards while reducing long-term operating costs.

For customized freeze-drying solutions or detailed technical documentation, please contact our expert team.

Havion — Empowering smarter, safer, and more efficient freeze-drying production.

Commercial Freeze Dryer System Overview

Product Conveying System

Equipped with wheeled 304 stainless steel trolleys and food-grade trays, this system minimizes cleaning tasks and reduces the risk of cross-contamination, ensuring a simple and efficient process.

Drying and Sublimation System

The drying and sublimation process is fully automated. Simply set the process parameters and press a button to start, simplifying operation.

Heating System

Temperature is precisely controlled throughout the range (from ambient temperature to 100°C), ensuring optimal product quality.

Vacuum System

Vacuum is achieved within 10-15 minutes, with the option to shorten the time for special requirements.

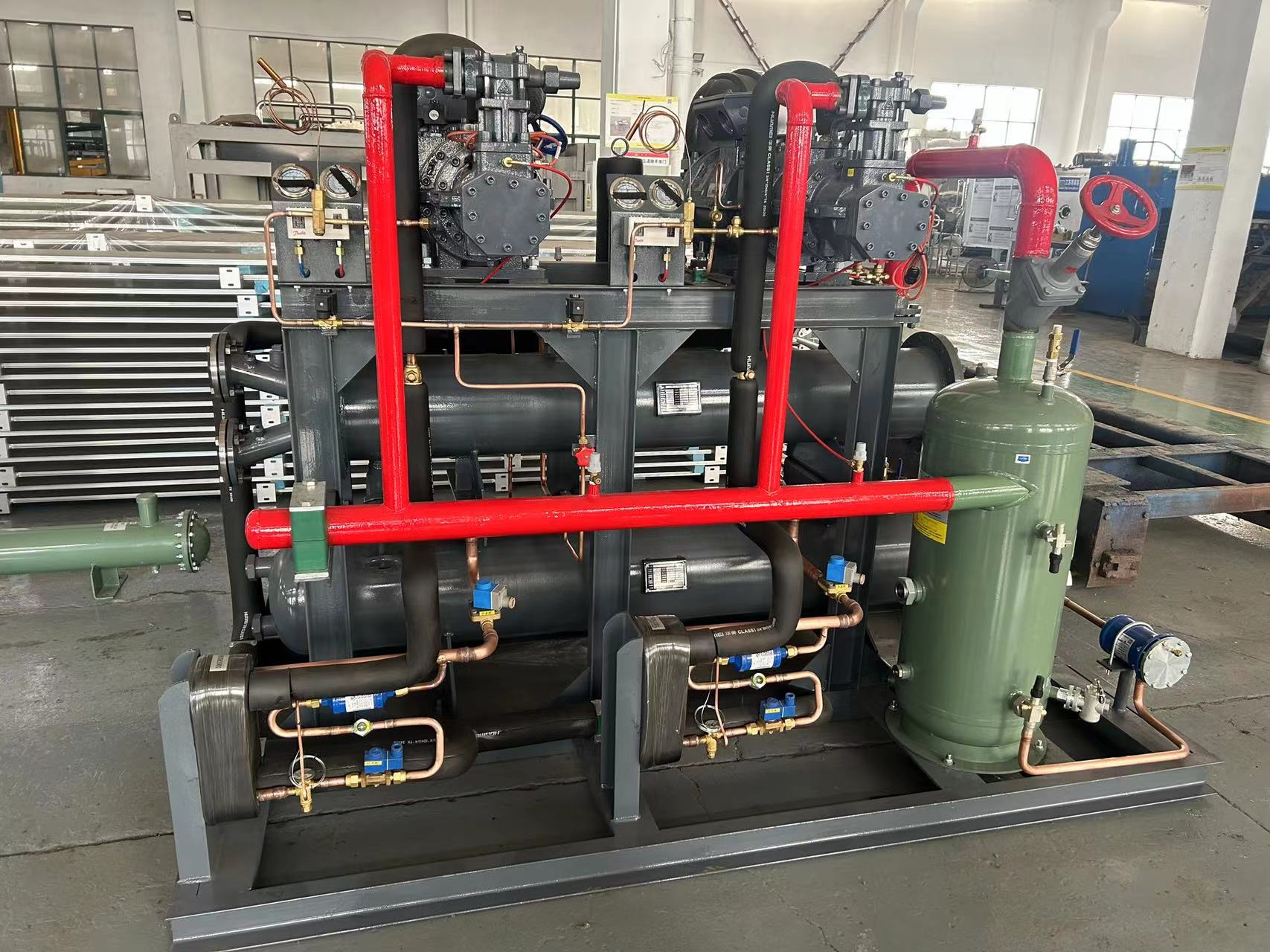

Refrigeration System

High-efficiency commercial compressors with multiple units running in parallel. The condensers share a system and operate alternately, reducing energy consumption.

Defrosting System

Water-flushing defrost completes in 60 minutes without interrupting the drying cycle, efficiently removing ice buildup. Easy to clean, low maintenance, and boosts system uptime by preventing ice-related disruptions.

Intelligent Control System

Advanced PLC control with automatic/manual modes. Offers real-time monitoring, data logging, curve export, and remote access. Ensures stability and meets CE/ISO9001 compliance.

Video

What industries do you serve, and how is your solution aligned with modern business needs?

We serve industries such as food processing, pharmaceuticals, and biotechnology, helping businesses improve efficiency, scalability, and profitability through advanced equipment and digital integration.

How do you price your solutions? Do you offer scalable options?

Our pricing is flexible and based on project scale, customization, and service levels. We support both small-scale and large-scale operations.

How do your services support operational growth and brand value?

Our solutions improve productivity and consistency, which helps build strong brand identity while reducing long-term operational costs.

Can your products be tailored to our business and end users?

Yes. We offer personalized configurations to suit your production environment and customer expectations.

How do you ensure a reliable and trustworthy customer experience?

We provide dedicated support, transparent communication, and high-quality equipment built for durability and ownership longevity.

What technology do your systems use? Are they user-friendly?

Our machines feature smart control systems, automation, and AI diagnostics. They are designed for ease of use and minimal training.

Can your system be integrated with our current software or web-based infrastructure?

Yes. Our solutions support API integration, remote monitoring, and are compatible with mainstream enterprise systems.

Is technical support included?

Full technical support and onboarding are provided, with optional long-term service agreements.

Do your solutions support packaging, storage, and transportation?

Yes. Our commercial freeze dryers are designed to integrate seamlessly with packaging-ready systems optimized for logistics, safe storage, and smooth transport. These systems are perfect for handling a wide range of products, from food to pharmaceuticals.

What’s included in the purchase? How is payment handled?

We provide detailed proposals with payment terms, optional training, and delivery services. For large-scale orders, such as freeze dryer commercial systems, multi-stage payments are available. We offer flexible options depending on the project’s scale, including the commercial freeze dryer machine.

Are your systems suitable for daily-use consumer products?

Absolutely. Our commercial freeze dryers are used to produce ready-to-eat meals, snacks, and health foods that cater to modern family needs. Whether you’re looking to scale production or purchase a commercial freeze dryer for sale, our technology supports high-quality processing for daily-use consumer products.

How much does a commercial freeze dryer cost?

The commercial freeze dryer price varies based on the model and specifications, but we offer competitive pricing tailored to meet your production needs. Feel free to contact us for a customized quote for commercial freeze dryers designed to boost your operations.

Commercial Freeze Dryer Applications

Food Industry

Candy & Snacks

Maintains original flavor and crisp texture, ideal for both fruit and vegetable-based snacks.

Extends shelf life, ideal for packaging and distribution.

Supports the growing demand for healthy and preservative-free treats, including meat-based snack options.Cooking & Ready Meals

Suitable for various recipes, including soups, main dishes, and snacks, incorporating meat, vegetables, and fruits.

Allows for pre-roasting treatments before freeze drying to preserve smoky flavors in meat and vegetable dishes.

Fast rehydration for convenient meal preparation, ideal for fruit and vegetable combinations.Food Preservation

Locks in color, aroma, and nutrients in meat, vegetables, and fruits.

Extremely low moisture content prevents microbial growth.

Ideal for seasonal ingredient storage, including fruits, vegetables, and meats.Taste & Texture Optimization

Enhances taste retention, particularly for fruits and vegetables.

Maintains structure and crunch, ideal for meat, fruit, and vegetable snacks.

Supports premium food development, including high-quality meat and vegetable options.Nutrition & Health

Nutritional Supplements

Preserves the activity of essential nutrients like vitamins, proteins, and enzymes, including those from fruits and vegetables.

High absorption rate; easy to process into powders or tablets, ideal for meat-based supplements.

No need for artificial preservatives, ensuring the natural integrity of meat, vegetable, and fruit supplements.Health & Functional Foods

Freeze drying retains health-enhancing compounds in vegetables, fruits, and meat-based products.

Ideal for specialized diets and low-temperature cooking applications, including for meat and vegetable dishes.Medication & Pharmaceuticals

Suitable for vaccines, biologics, and oral drugs requiring cold preservation, including supplements derived from fruits and vegetables.

Increases product stability and shelf life, particularly for pharmaceutical applications involving meat or vegetable-derived ingredients.

Ensures active ingredients remain effective, whether from fruits, vegetables, or meat-based sources.Machine & Engineering Solutions

Freeze Drying Machines

Available in various capacities for small to large-scale production, including for meat, vegetable, and fruit-based products.

Advanced control systems for precise temperature and vacuum regulation, adaptable to both meat and vegetable applications.

Supports automation and continuous batch operations, ideal for meat, vegetable, and fruit processing.Choice & Customization

Drying curves tailored to the specific characteristics of different food or drug types, including meat, vegetables, and fruits.

Adaptable to diverse industry needs—from food processing plants to pharmaceutical labs, suitable for products ranging from meat to fruits and vegetables.

what food preservation

What Food Preservation Really Means: Strategies, Technologies, and Outcomes Food preservation refers to the set of techniques and processes used to slow down or halt the spoilage of food. At its core, it’s about extending the shelf life of food products and maintaining their nutritional value, flavor, and texture. Whether

Freeze Drying Process Steps Explained: From Ice to Shelf-Ready

Freeze-drying isn’t just a method—it’s a transformation. From juicy strawberries to injectable pharmaceuticals, the ability to preserve texture, structure, and biological activity rests on one thing: precision. But what exactly happens between raw material and final powder? Let’s walk through each step of the freeze-drying process and break it down

Behind the Cold: Unpacking the Freeze Drying Process Steps

Freeze drying, also known as lyophilization, preserves perishable materials by removing water through sublimation—transitioning from a solid directly into vapor without passing through the liquid phase. It’s not just a modern innovation; ancient civilizations, particularly the Incas, laid its foundation by storing food at high altitudes where cold nights and