Compared to freeze-drying machines from 30 years ago, are modern ones more advanced? Let me say something that might offend my peers—for many Chinese food freeze-dryer manufacturers, not only is there no progress, but in some cases, we’ve even regressed!

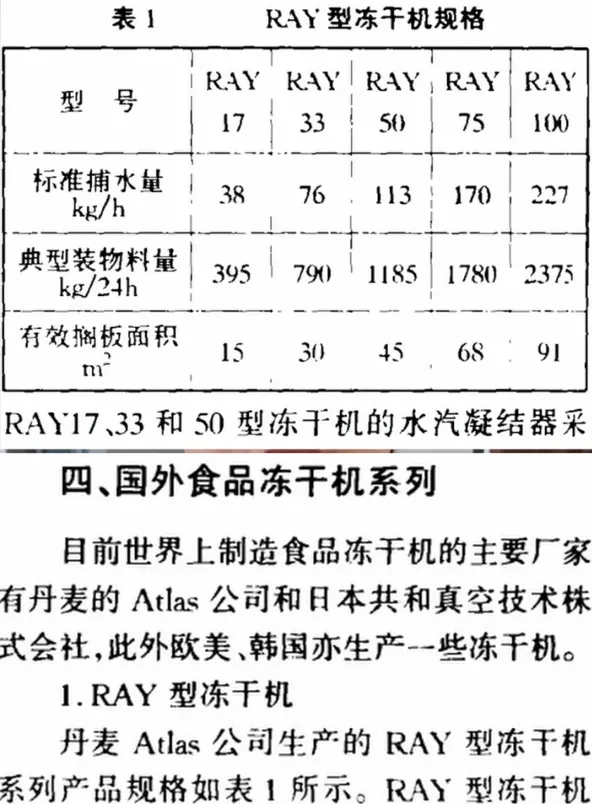

Take a 1994 research paper that detailed the specs of foreign freeze-dryers back then. Based on the effective shelf area and standard water replenishment rate, we can calculate that their evaporation intensity per square meter was around 2.5 kg/h. What does this mean?

Remember my freeze-dried milk experiment? With a loading capacity of 14.9 kg of fresh material per square meter, drying took just 11.5 hours. Or the chicken breast test—14 kg per square meter, dried in 12 hours. And guess what? Machines from 30 years ago could already achieve this!

Now, fast forward to today. How many domestic freeze-dryer manufacturers are still loading just 9–10 kg per square meter, while taking 20–30 hours to dry? How embarrassing is that?

Too many companies saw the food freeze-drying boom and jumped in just to cash in—without real R&D investment, just marketing gimmicks like misleading “square meter” claims. Do they even realize their “1 square meter” performance isn’t even close to what was possible decades ago?

Want proof? I record the entire drying process with surveillance cameras—transparently showing clients exactly how much raw material your machine can handle per square meter and how long drying really takes.

And yet, some of these manufacturers boast about being “20-year veterans” in the industry. Forget checking their business licenses—let’s assume they’re telling the truth. But after all that time, is this really the best they can do? Thirty years to catch up, and this is the result?

Meanwhile, at FiE 2023 (Food Ingredients Europe), a company unveiled a proprietary fluid dynamics model, redesigning their classic freeze-dryer and boosting its already high absorption efficiency by another 20%. Of course, we’re already studying their new approach.

As for those domestic competitors I just called out? My advice: Put your effort where it matters—into your machines.

🚀 Unlock a New Era of Food Preservation – Your Business Success Starts with Havion!

Why Have 300+ Global Food Companies Chosen Havion Freeze Dryers?

✅ Efficiency Revolution: TriCore™ technology boosts drying speed by 22% and reduces energy consumption by 35%

✅ Zero-Compromise Quality: -45°C ultra-low temperature condensation locks in 99.9% nutrients and flavor

✅ Compliance Guaranteed: CE/ISO certified for seamless audits 📈 Act Now to Lead in Food Preservation!

👉 Get Custom Solutions | Home Freeze Dryers | Commercial Freeze Dryers | Industrial Freeze Dryers

👉 24/7 Rapid Response: [email protected] | +86 15621636128 #FreezeDryingTech #FoodInnovation #ZeroWasteRevolution

Havion – Where Every Bite of Freshness Becomes Eternal 🌱